Order Manager

Version 8

Order Manager

Version 8

Contents of this Topic: Show

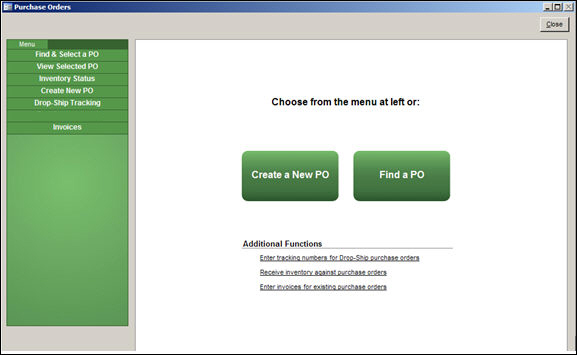

To access the Purchase Orders screen, go to Main Menu>Manage My Inventory>Manage My Purchase Orders

Monsoon Order Manager's Purchase Order system is used to order and track regular inventory purchased from suppliers. In Version 8, purchase orders are created and invoiced in the Monsoon Order Manager and they are received in the Monsoon Fulfillment Manager.

The program can create purchase orders in a semi-automatic fashion, basing its decisions on the current ATP, the number of units needed for unfilled orders, the quantity of units already on order from the supplier, and the re-order point of each item. It also adheres to supplier minimum order quantities and other purchasing rules, such as purchasing in lots.

System parameter POCalcMethod denotes the method by which the program determines which items should be added to a purchase order. The choices are Order Quantity, Target Quantity, and Delayed Target.

Inventory records must have a Primary Supplier designated to be eligible for the program to add them to a purchase order when using Needed or Refills, however, AllSKUs does not. Just as its name suggests, AllSKUs adds every SKU to the purchase order. If the target or reorder quantity is already met, it adds the supplier's minimum order quantity to the purchase order.

When merchandise from a regular purchase order is delivered to the merchant, it must be "received" and "invoiced" in Stone Edge completing the life-cycle. Invoice information can be exported to QuickBooks as "Bills" to be paid.

Of course, purchase orders can also be created manually. You can select the items and quantities you want to order rather than relying on the program to calculate it for you.

Barcode labels can be printed for all items on a PO at the time it is being received by the Monsoon Fulfillment Manager.

If you drop-ship merchandise, you can also place and track those sales through the Monsoon Order Manager purchase order system, but the creation and management of those purchase orders is slightly different than purchase orders for regular inventory. Tracking data can be entered manually or imported from a text file for drop-ship purchase orders. The program can also create packing records for drop-shipped merchandise. Refer to the topic on Drop Ship Purchase Orders for more information.

Drop-ship purchase orders refer to items which are shipped directly to the customer from the vendor - the merchant never takes possession of the merchandise. The drop-ship purchase order life-cycle exists entirely in the Monsoon Order Manager, the Monsoon Fulfillment Manager does not have any knowledge of drop-ship purchase orders.

Drop-ship purchase orders can be managed by the Monsoon Order Manager purchase order system, but they are handled differently than regular purchase orders. Drop-ship purchase orders are created at the Process Orders or Multi-Order Processor screens of Monsoon Order Manager, which is generally installed at the company headquarters. Once a drop-ship purchase order is created, any changes to the purchase order take place at the Purchase Order screen. Tracking information for drop-shipped items can be imported from a text file into the Monsoon Order Manager. Invoices for drop-ship purchase order invoices are received in Monsoon Order Manager (Create Purchase Orders>Enter or Import Tracking Data>Enter Invoices). Refer to the topics relating to drop-ship purchase orders for more information.

"Regular" purchase orders refer to merchandise that is stocked by the merchant as opposed to items that are drop-shipped.

Regular purchase orders are created in Monsoon Order Manager at the company headquarters and are communicated to the vendor and the Monsoon Fulfillment Manager, which is generally installed at the warehouses. When the vendor delivers the merchandise to the warehouse, it is "received" into the Monsoon Fulfillment Manager, which informs the Monsoon Order Manager of the status of the purchase order and the changes to the item's QOH. The supplier's invoice for the purchase order is processed in the Monsoon Order Manager, which is generally installed at the company headquarters. If you use the Monsoon Order Manager/QuickBooks integration, purchase order invoice information can be exported to QuickBooks as "bills" to be paid.

Once invoices have been entered, they can be exported to QuickBooks as bills to be paid. Unfortunately, the purchase order process presents challenges for a lot of merchants:

POs may need to be changed between the time they are placed and the time they are received.

After a purchase order is placed, you may find that your costs are different from what you expected.

The actual products and quantities you receive may differ from what you ordered.

Invoices may include all or portions of multiple POs.

To accommodate issues like these, we developed the concept of "loosely connected data." For each purchase order, Monsoon Order Manager stores what was originally ordered, what is currently expected (if not already received), what is received and what has been invoiced. Each stage is "loosely connected" to the other stages, so almost anything can be changed until the items have been received and invoiced. Each purchase order’s original details are "locked" once it has been added to a purchase order invoice. You can still modify "expected" and "received" information for the PO, but not the original details.

Purchase Orders screen

this accordion link allows you to close purchase orders that have Expected items which have not been Received by the cancellation date set when the purchase order is created

it assumes you will create a purchase order for those items with another supplier

see a combined list of all line items from the current list of purchase orders

Created: 5/10/12

Revised: 4/2/15

Published: 08/19/15