Version 8 FM

Version 8 FM

Contents of this Topic: Show

Assemblies are special inventory SKUs which are comprised of two or more individual inventory items used to create a finished product. Individual components of an Assembly can be sold by themselves as well as part of an Assembly.

The process of creating an assembly involves the creation of an inventory record representing the finished product, and then assigning the regular inventory records of the components as part of the assembly. When that is complete, you logically "build" the QOH of Assembly SKU, which is tracked by the program, just a any regular inventory item is tracked. When Assemblies are built or broken, the inventory quantities for the both the Assembly SKU and the individual component SKUs change. For instance, when an Assembly SKU is built, the QOH of its component parts decreases while the quantity on hand of the Assembly increases, effectively transferring inventory from the component SKUs to the Assembly SKU. Likewise, when an Assembly SKU is "broken-down", the inventory counts of the component SKUs increase, as the QOH of the Assembly SKU decreases. The cost per unit of the Assembly SKU can be derived from just the parts or it can include the cost of the parts plus labor, packaging and handling fees, etc.

Assembly SKUs (and component SKUs) are

defined in the Monsoon Order Manager

and are sent to the Monsoon Fulfillment Manager,

where they are "built" from the warehouse's component SKUs.

Unlike a Kit SKU, orders for an Assembly SKU will never show the individual components as line items, and the quantity on hand and cost information is tracked by the Assembly SKU, itself, not by its component SKUs.

Another difference between Kits and Assemblies is that it is possible to breakdown an Assembly SKU into its parts in order to satisfy order demands for the individual components if necessary. Kits do not have any cost or QOH values associated with them; that information is tracked or obtained from the individual component SKUs instead.

Just as with Kits, it is a best practice to create a new Assembly SKU if the component part list should change after the finished Assembly has been sold. Until that time it is fine to alter the component list of the Assembly SKU.

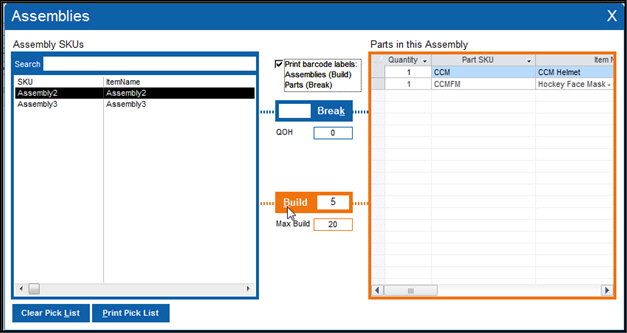

lists the SKU and Item Name of all of the assemblies defined in the system by default

select one from the list to build more units from its components or to break existing units down into its components

select this to clear all pick list data from the current session

do this after each "build" or "break" action

if selected, the program prints barcode labels for the number of Assemblies SKUs that are "built", or the components of Assemblies that are "broken"

select this before building or breaking an assembly

if you only want to print labels for a few of the components, manually clear the check mark in the Print column of the Parts in this Assembly section view image

do not clear the Print Labels check box and then manually select the box in the Print column of the individual rows or the report is not generated

select this to create the number of assemblies specified in the adjacent text field or up to the value in the Max Build field

the program does the math and changes the QOH of the affected component's inventory records accordingly

all of the component parts of the selected Assembly SKU are listed here

the information about each component is displayed in the following columns:

shows the number of units of the component needed to complete the Assembly

shows the inventory SKU of the component

shows the name assigned to the component SKU

shows the current quantity on hand for each of the components, used to calculate the number of Assemblies that can be built

indicates the inventory record for the component SKU is marked as Ignore ATP

all items are selected by default, and barcode labels are all of them if Print barcode labels is selected

clear this field and barcode labels are not printed for the item(s) view image

Created: 1/28/14

Revised: 6/24/15

Published: 08/19/15